Find the Perfect CNC Machine for Your Needs—Get a Personalized Quote Today!

Request a quote and the sales professional who represents Hurco in your area will contact you to assess your needs.

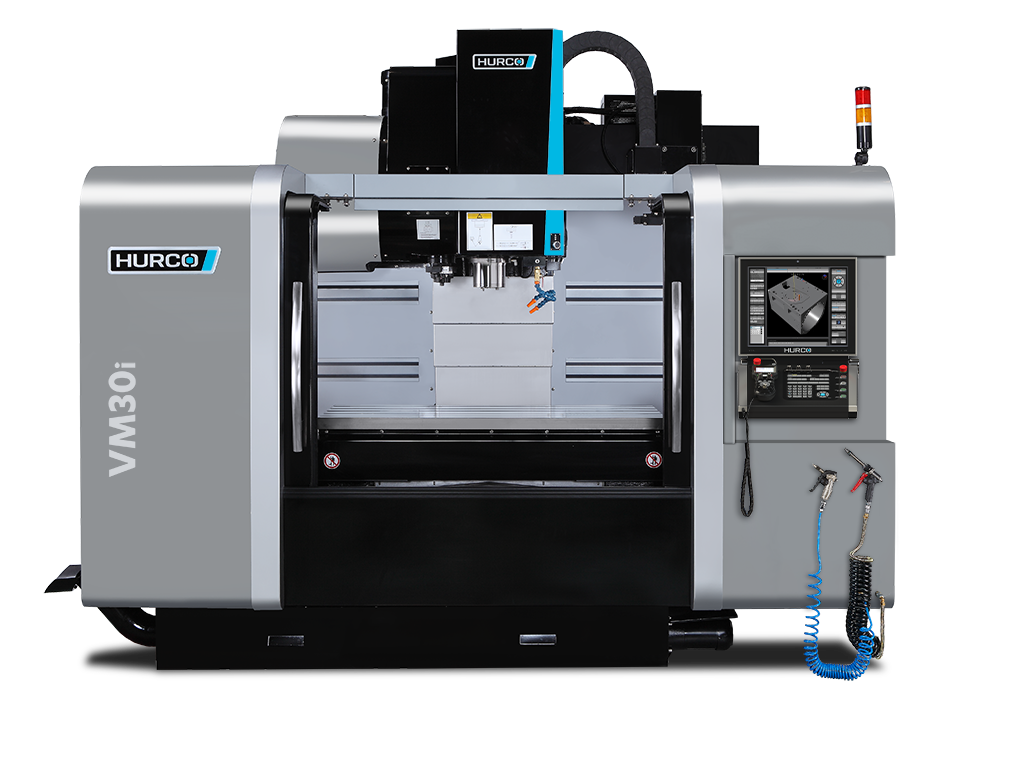

Why Hurco CNC Machines?

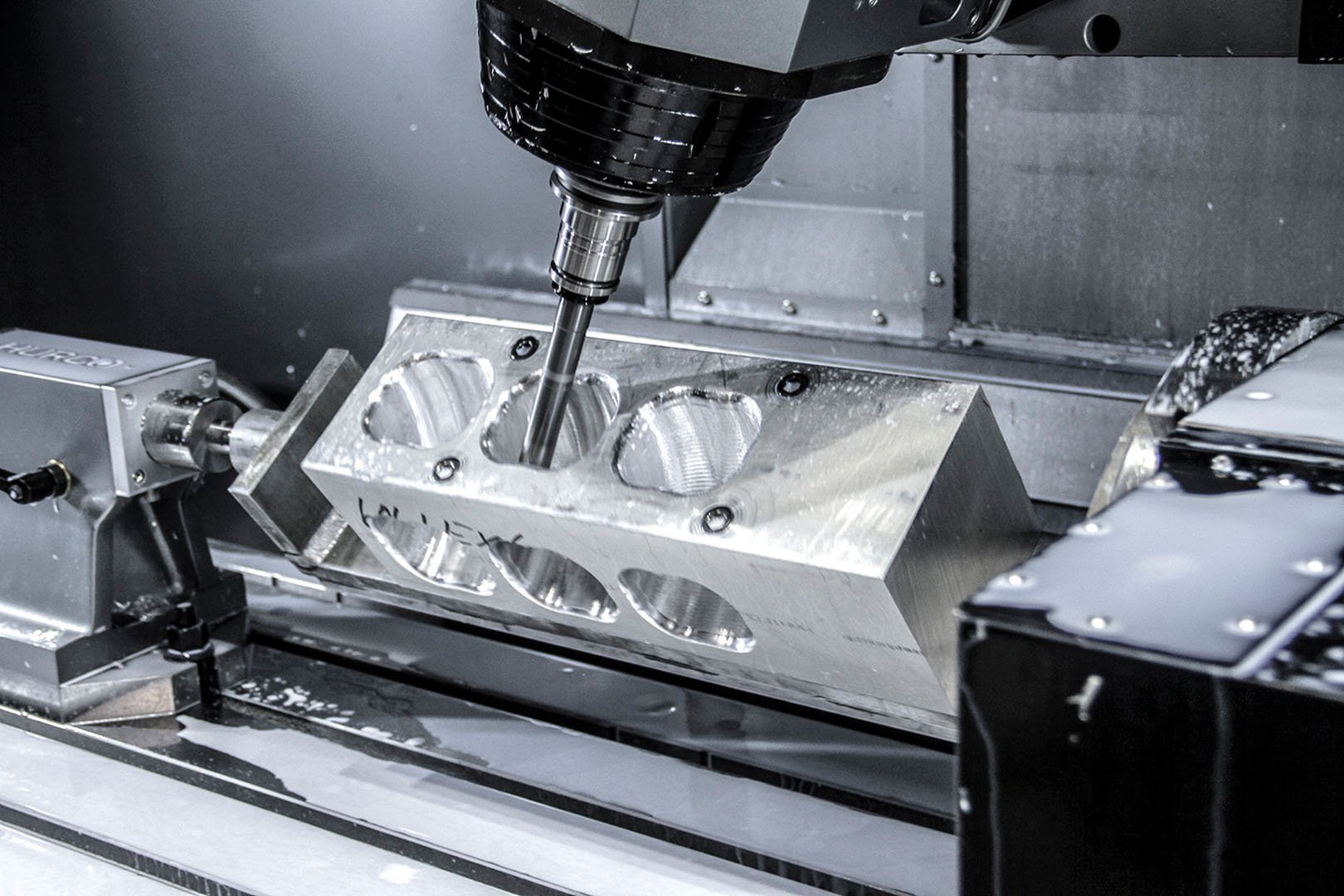

Hurco machines are built to deliver performance, precision, and profitability for job shops of all sizes. Here’s why our machines stand out:

- Innovative Control Technology: Our WinMax control system delivers cutting-edge capabilities, making machining easier and more efficient.

- Durability & Reliability: Designed for long-term performance, Hurco machines are engineered to handle tough jobs while maintaining precision.

- Personalized Support: Our dedicated sales and service teams are available to assist you every step of the way, ensuring you get the most out of your investment.

- Customization Options: Choose from a wide range of machines, configurations, and options that are tailored to your specific needs.

Fill Out the Form to Get Started

Please Note: Hurco CNC machines are sold by our distributor partners throughout North America.

For international requests please click here to select your country first >>

For international requests please click here to select your country first >>